-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

blog

ORNTA5-1T0 Datasheet Deep Dive: Specs & PCB Footprint

Comprehensive analysis of mechanical, electrical, and thermal parameters for reliable hardware production and CAD integration. When power-stage and RF components are integrated without rigorous datasheet parsing, layout errors and thermal misses commonly cause board re-spins and assembly failures. This article walks through a hardware-focused, step-by-step deep dive into the ORNTA5-1T0 datasheet to extract the mechanical, electrical, and thermal figures that matter and produce a correct PCB footprint for reliable production. The goal is practical: identify the exact dimensions to capture, the electrical and thermal limits that drive copper and via choices, and a verified footprint workflow designers can follow for CAD handoff and pre-production checks. Recommendations emphasize measurable checks and a verification checklist that reduces first-pass failures. Product Overview & Mechanical Basics Mechanical Package & Dimension Callouts Start by transcribing the package name, code, and the 2D dimension table from the official datasheet into a single reference drawing. Capture body length/width, overall height, lead/terminal pitch, and exposed-pad outline. Note tolerances for each dimension and add tolerance handling (± values) to pad design so manufacturing variability does not cause misalignment during pick-and-place and reflow. Pinout & Functional Grouping Map pin numbers to functions: power input, power output, ground, sense/feedback, and exposed thermal pad. Produce a simple pinout table for the footprint library showing pin number, net name, and function. Flag high-current pins and the exposed pad as requiring wider copper, thermal vias, and short return paths — these demand special layout attention early in the CAD flow. Electrical & Thermal Specs Analysis Parameter Category Critical Data Points Layout Impact Absolute Maximums Voltage, Current, Peak Power Trace width, clearance requirements Thermal Resistance RθJA, RθJC, Max Tj Thermal via count, copper pour area Signal Integrity Input/Output leakage, Switching freq Decoupling placement, EMI shielding Thermal Performance Visualization Estimated Junction Temp (ΔT) based on Pd: Ambient Typical Load Max Rating (Danger) Pull RθJA and RθJC, maximum junction temperature, and any thermal impedance curves from the datasheet. Use Pd × RθJA to estimate ΔT above ambient and plan a PCB strategy: exposed-pad area, thermal via count and placement, and copper pour connectivity. Recommend via sizes, via counts, and placement grid to meet the calculated ΔT for expected ambient and power dissipation. PCB Footprint & Land Pattern Recommended Land Pattern from Datasheet Convert 2D dimensions to SMD pad sizes by mapping body-to-pad clearances, terminal length, and lead pitch. Define SMD pad length and width to accommodate fillet formation and pick-and-place tolerances. Add soldermask clearance and a courtyard at recommended distances. Keep the land pattern adaptable to ± tolerance by designing pads slightly larger within assembly constraints to improve yield. Pads Optimized for fillet and reflow stability. Soldermask 1:1 or slightly expanded (0.05mm). Silkscreen Clear orientation marks, non-overlapping. Example Footprint Case Study & Common Pitfalls Workflow: Datasheet to CAD Import: Load datasheet 2D drawings as a background layer. Geometry: Create padstack for terminals and the central thermal pad. Expansions: Assign precise soldermask and paste mask layers. Thermal: Place the calculated thermal via grid (e.g., 3x3 or 4x4). Validation: Run DRC and verify against the 3D STEP model. Top 6 Assembly Mistakes ❌ Incorrect pad-to-pad spacing ❌ Omitted thermal vias in high-power zones ❌ Insufficient soldermask expansion ❌ Ignored tolerance stack-up during layout ❌ Wrong paste coverage (too much/too little) ❌ Silkscreen printed over component pads Final Design Checklist & Handoff Pre-production Checklist Verified land pattern dimensions Thermal via count vs. Pd requirement BOM pad compatibility check 3D model clearance (Z-height) Orientation and inspection markers Deliverables for Manufacturing CAD Footprint & 2D Drawing Recommended paste stencil specification Thermal via drill chart Pick-and-place coordinates Internal sign-off flow document Key Summary Capture ORNTA5-1T0 mechanical dimensions precisely: body size, pad pitch, and exposed-pad outline, and include tolerance handling in the padstack to prevent assembly misalignment. Translate datasheet electrical specs into PCB rules: calculate Pd, use RθJA for ΔT, and convert allowable current into trace width and copper weight using IPC guidance. Design the PCB footprint with correct paste coverage, thermal via grid, and soldermask clearances; verify with DRC, 3D fit, and a pick-and-place test before release. Common Questions & Answers What datasheet fields are essential for a correct PCB footprint? + Essential fields are the 2D mechanical drawing (with tolerances), recommended land pattern or pad dimensions, terminal pitch, exposed-pad outline, and recommended soldermask and paste apertures. Also capture maximum standoff and height to ensure mechanical clearance and 3D model fit for enclosures and nearby components. How do I size thermal vias for the exposed pad? + Choose via diameter and annulus consistent with your board shop capability, typically 0.3–0.5 mm finished drill for high-power pads. Use a grid with enough vias to meet thermal resistance targets calculated from Pd × RθJA, and stagger vias to improve thermal spreading. Document via fill or tenting requirements for assembly. How do I verify the footprint before fabrication? + Run DRC with manufacturing rules, import a 3D model to check mechanical fit, generate a paste and stencil preview, and produce pick-and-place coordinates for a test-run. Perform an internal review checklist and, where possible, place a physical part on a test coupon to confirm pad alignment and solderability before full production. Summary A correct ORNTA5-1T0 footprint and layout come from parsing the mechanical, electrical, and thermal datasheet sections and converting them into concrete padstacks, thermal via strategies, and verification steps. Verify dimensions, implement thermal vias per calculated Pd and RθJA guidance, follow paste coverage recommendations, and run final DRC and 3D checks before production release.

4 February 2026

0

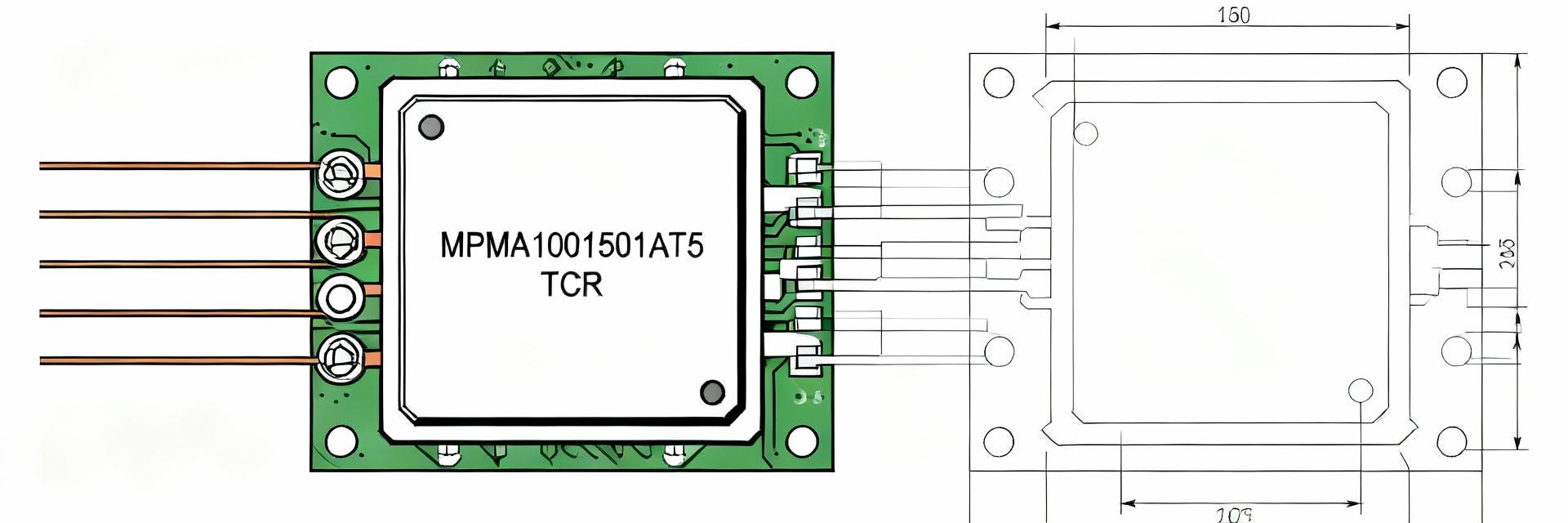

MPMA10015001AT5 Datasheet Deep Dive: Specs & TCR Footprint

Modern thin-film resistor networks commonly specify ratio drift in the single-digit ppm/°C range and absolute tolerances down to 0.1%—metrics that determine whether a divider or sense resistor meets high-precision system requirements. This article delivers a practical, data-driven deep dive into the MPMA10015001AT5 datasheet, focusing on the specs that matter, TCR behavior in real use, and recommended PCB footprint and layout practices to ensure reliable performance in precision ADC front ends and sensor systems. Quick background & what to look for in the MPMA10015001AT5 datasheet Part family context & core role in designs This part is a precision thin-film resistor network designed for matched divider and sensor bridge applications, commonly used at ADC inputs, voltage-reference dividers, and differential sense resistor networks. Designers should prioritize datasheet sections on resistance options, absolute tolerance, ratio matching, ratio drift, TCR, power per element, and mechanical/footprint drawings. Recommended quick checks before layout or ordering Before laying out or ordering, run a short checklist: confirm DC resistance and absolute tolerance, verify resistor-ratio tolerance and ratio-drift spec, check per-element power rating and derating instructions. Red flags include ratio mismatch greater than 0.1% and a TCR that exceeds system temperature drift allowances. Key electrical specs — decode the numbers that matter The datasheet lists available DC resistance codes and absolute tolerances; absolute tolerance (e.g., 0.1%) denotes initial deviation from nominal, while ratio tolerance quantifies matching between paired elements. For divider error translation: a 0.1% absolute tolerance on each resistor in a 2-resistor divider at 3.3 V can create up to ~3.3 mV of offset from tolerance alone. Parameter Typical Datasheet Value Why it matters Absolute tolerance 0.1% (example) Sets initial DC offset and calibration load Ratio tolerance 0.02% (example) Controls divider balance and common-mode rejection TCR (per element) ±25 ppm/°C (example) Determines temperature-dependent resistance change Ratio drift ±2 ppm/°C (example) Critical for divider stability over temperature Power per element 0.063 W (example) Limits dissipation and self-heating errors TCR & ratio-drift deep-dive — what the numbers mean in practice Absolute TCR (ppm/°C) describes how a single resistor's value changes with temperature; ratio drift (ppm/°C) describes how the balance between matched elements shifts. In many applications, ratio drift is the more critical metric. Absolute TCR Impact (25 ppm/°C) 3125 ppm total drift (@125°C ΔT) Ratio Drift Impact (2 ppm/°C) 250 ppm total drift (@125°C ΔT) * Visualizing the significant advantage of matched ratio drift over absolute drift in differential circuits. "For matched networks, ratio drift is often more important because common-mode TCR cancels in a divider. Example: with absolute TCR = 25 ppm/°C and ratio drift = 2 ppm/°C, over a 125°C span, the divider imbalance shifts only ~0.025%." Footprint, package dimensions & PCB layout best practices Thermal and layout tips • Keep matched resistors physically close on the same thermal island to promote common-mode temperature stability. • Avoid routing high-current traces or placing hot ICs adjacent to the resistor network. • Use thermal vias sparingly; maintain symmetry around the network. The "Don'ts" Checklist × No large asymmetrical copper pours under the part. × Avoid thermal asymmetry under only one resistor element. × Don't ignore solder mask clearance guidelines. Actionable design checklist & procurement notes Design Sign-off ✔ Verify DC resistance vs. system error budget. ✔ Confirm ratio tolerance meets divider needs. ✔ Plan PCB thermal symmetry. Procurement Use long-tail search queries such as "MPMA10015001AT5 datasheet TCR performance" to locate independent test data. Keep a BOM alternative list with similar matched thin-film networks to mitigate long lead times. Frequently Asked Questions How does MPMA10015001AT5 TCR affect divider accuracy? + TCR changes alter absolute resistance with temperature; however, for matched networks the ratio drift (ppm/°C) typically dominates divider imbalance. Designers should use the ratio-drift spec to predict output shift over the operating range and convert ppm/°C into mV at the system reference to determine if calibration is required. What footprint considerations are critical for MPMA10015001AT5? + Critical items include exact pad dimensions, paste aperture percentage, solder mask clearance, and courtyard margins per the mechanical drawing. Ensure symmetric copper and short traces to avoid thermal gradients; adjust stencil apertures to prevent tombstoning and to control solder fillet formation. What lab tests should be performed to verify performance? + Essential tests: initial DC resistance and matching check, thermal sweep to measure TCR and ratio drift, power soak to reveal self-heating effects, and long-term drift or accelerated aging if reliability is critical. Log results with timestamps, ΔT, and calculated ppm/°C values. Summary: Reliability Through Precision MPMA10015001AT5 drives precision performance through low-drift behavior. Validate datasheet claims in the lab, follow symmetric layout guidelines, and utilize the provided checklist to ensure predictable system accuracy.

3 February 2026

0

MDP1603100KGD04 Performance Report — Key Specs & Limits

Measured and datasheet values for the MDP1603100KGD04 show a 250 mW power-per-element rating, ±100 ppm/°C TCR, and an operating window from −55°C to +125°C. These parameters define its usable thermal limits and derating strategy. Product Overview — MDP1603100KGD04 at a Glance Key Nominal Specifications Parameter Value / Description Element Count Multiple-element array (refer to datasheet) Package / Pin Count Chip-array package, multi-lead Resistance Value(s) Application-dependent; select per design requirements Power per Element 250 mW (Continuous, Ambient-limited) TCR ±100 ppm/°C Rated Operating Temp −55°C to +125°C Typical Tolerance Datasheet typical tolerances; use matching specs for networked use Mounting / Footprint SMD footprint; PCB copper and via strategy affect thermal path Summary Point: The table lists the critical specs designers must parse. Power-per-element and TCR are explicit datasheet numbers. These are absolute electrical ratings; typical tolerance and matching are performance statistics that should be validated in production sampling before use in precision circuits. Typical Applications & Constraints This device is suited for precision resistor arrays, matched networks, and low-power signal paths. With a 250 mW rating per element and ±100 ppm/°C TCR, it is ideal for precision voltage dividers, sensor signal conditioning, and matched attenuators. ✔ Recommended Use ● Precision voltage dividers ● Sensor signal conditioning ● Matched attenuators ✘ Critical Constraints Avoid power-distribution roles or high-current shunt applications where single-element dissipation exceeds the 250 mW limit. Not ideal for power-sharing without distribution across elements. Electrical Performance & Tolerance Analysis Resistance Tolerance & Power Handling Tolerance and matching directly affect system error budgets. The 250 mW rating sets voltage and current ceilings per element. Example Calculation: Max Voltage (Vmax = √P·R) ~15.8 V R = 1 kΩ ~5.0 V R = 100 Ω Note: Values based on 250 mW limit. Temperature Coefficient (TCR) & Drift The MDP1603100KGD04 TCR performance (±100 ppm/°C) determines short-term and range drift. Over a −40°C to +85°C span (ΔT = 125°C), a ±100 ppm/°C drift yields a resistance change of ±1.25%. In matched arrays, common-mode drift can cancel, but mismatch in elements multiplies error. Thermal Behavior & Derating (Data-Driven) Operating Temperature Range Rated range is −55°C to +125°C, but usable dissipation falls with rising ambient temperature. Conservative guidelines suggest: Up to 70°C Ambient 100% Power (250mW) At 85°C Ambient ~73% Power (182mW) At 125°C Ambient 0% Power Thermal Path Considerations Maximize thermal vias under pads. Connect to internal or top copper pours. Isolate heat-sensitive neighboring elements. Use staggered thermal via patterns. Test Methodology & Qualification Recommended Test Setup & Procedures + Repeatable setup is essential. Document FR4 thickness, copper area per pad, and instruments (precision 4-wire DMM, thermocouples, thermal camera). Record element leads and substrate temperature over a 5–15 minute period to reach steady-state. Stress Tests: Power Soak & Thermal Cycling + Ramp element power in 10–20% steps holding to steady-state; thermal cycle −55°C to +125°C with 15–30 min dwell for multiple cycles. Perform long-duration soak at 85°C for endurance validation. Common Failure Signatures & Troubleshooting + Look for drift beyond tolerance, opens, or delamination. Root causes often include overpower, inadequate thermal paths, or mechanical assembly stress. Use thermal scans to reveal hotspots compared to expected profiles. Design Guidance — Integration Best Practices Derating Rules Operate at 50–70% of rated power at high ambient (above 70°C). Apply an additional 10–20% margin for long-term reliability in critical paths. PCB Layout Tips Use enlarged pads with thermal relief. Control solder volume to avoid tombstoning. Place high-heat sources apart to minimize thermal coupling. Validation Perform post-reflow resistance checks to detect assembly-induced shifts and validate with thermal imaging during full-load operation. MDP Performance Summary Core Capacity: 250 mW per element and ±100 ppm/°C TCR define the electrical and drift budgets. Thermal Strategy: Linear derating is required above 70°C; at 85°C, allowed power is approximately 182 mW per element. Actionable Design: Verify thermal performance on representative PCBs and maintain a 50–70% power buffer for mission-critical applications.

2 February 2026

0

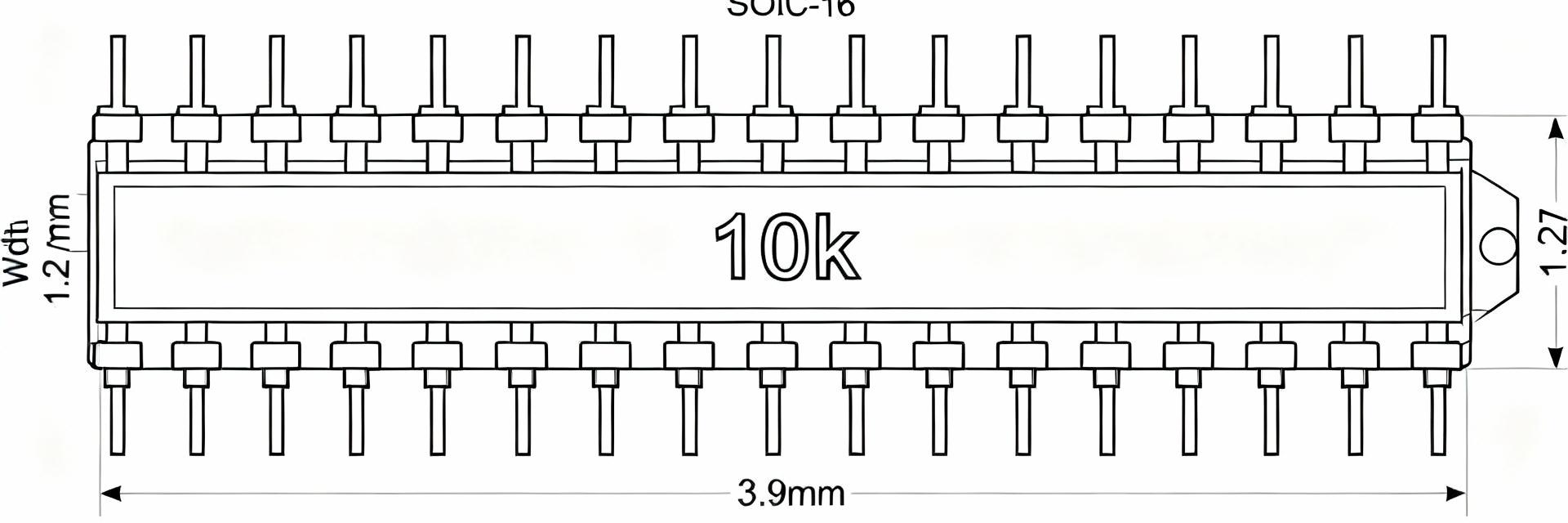

10k SOIC-16 Resistor Networks: Availability & Specs Report

Snapshot: US distributor inventory snapshots and marketplace data commonly show wide variability by tolerance and power rating for SOIC-16 10k resistor networks. Typical on-hand stock for 5% devices often exceeds that for 1% parts by a factor of two to three, while higher power-per-element variants trend toward multi‑week lead times. This report helps engineers and buyers assess availability, typical specs, and procurement actions. The goal is practical: summarize what a 10k resistor network in SOIC-16 looks like, which electrical and mechanical specs drive sourcing risk, and which short‑ and long‑term procurement tactics reduce outages. Readers will leave with a decision checklist, a comparison template, and clear next steps to evaluate fit and supply risk for production and prototypes. Background — What a 10k SOIC-16 Resistor Network is and Where it’s Used Basic Definitions & Configurations A 10k resistor network is an integrated array of nominal 10,000‑ohm resistors packaged together, commonly in a 16‑pin SOIC (SOIC‑16) surface‑mount package that houses eight discrete elements. Topologies are typically isolated (each element independent) or bussed (one common node shared by multiple resistors). Element count, pinout and whether the device is bussed versus isolated determine circuit compatibility and replacement options. Typical Applications SOIC‑16 resistor arrays are used for pull‑ups/pull‑downs on I/O buses, input termination networks, sensor line balancing, and compact divider banks. Designers choose arrays for PCB area savings, improved matching and assembly simplicity; trade‑offs include lower per‑element power handling and fixed pinouts versus the flexibility of discrete resistors when extreme power or custom spacing is required. Availability Landscape — US Inventory & Lead-Time Snapshot Visualizing typical market stock levels based on component specifications. Standard Tolerance (±5%) High Availability Precision Tolerance (±1%) Moderate / Limited High Power / Special Termination Long Lead Time Current Availability Signals Key metrics: reported stock quantity, quoted lead time, lifecycle status, and minimum order quantity (MOQ). Monitor authorized distribution snapshots and flagged lifecycle changes to gauge real shippability. Impact of Specifications Tighter tolerances (±1% vs ±5%), higher power per element, or extended temperature grades typically reduce available inventory and increase lead times. ±5% isolated arrays remain the most accessible. Specs Deep-Dive — Electrical and Mechanical Parameters Electrical Parameters to Compare Resistance: Nominal 10k standard value. Tolerance: Ranges from ±5% down to ±1% for precision. TCR: Temperature Coefficient (ppm/°C) impacts drift. Power: Typically 50–200 mW per element. Isolation: Resistance between independent elements. Mechanical/Footprint Considerations Watch SOIC‑16 body length (~0.30–0.35 inches), width, and lead pitch. Ensure thermal relief and soldermask clearance for consistent reflow. If assembly constraints exist, verify pin-to-pad compatibility for alternate 16-lead packages. How to Choose the Right Network Decision Checklist ✓ Confirm topology (isolated vs bussed) and pinout match schematic. ✓ Set tolerance and TCR margins based on accuracy needs. ✓ Specify power per element with thermal derating. ✓ Validate footprint and reflow profile with assembly house. Substitution Rules Acceptable substitutions must match resistance value, footprint/pinout, and have equal or greater power/TCR performance. Warning: Never substitute a bussed part for an isolated array without schematic verification to prevent functional regressions. Representative Part Types & Comparison Template Comparison Field Technical Notes Manufacturer-neutral label Unique short identifier for BOM tracking Resistance & Tolerance Standard: 10k, ±1% / ±2% / ±5% TCR (ppm/°C) Impact on thermal drift and stability Power per Element Measured in milliwatts (mW) Topology Isolated or Bussed configuration Package Dims SOIC-16 standard land pattern dimensions Lifecycle Status Active / EOL / Not recommended Suggested Substitutes Pre-qualified matched spec alternatives Procurement & Availability Action Plan Short-Term Sourcing Multi-source early and secure common-tolerance stock. Prequalify cross-reference parts like VSOR1601103JUF to identify lifecycle moves and substitute candidates quickly. Validate traceability when using market brokers. Long-Term Mitigation Allow broader tolerances where acceptable and design package-flexible footprints. Maintain an approved-alternates list and include lead-time cushions in BOMs. Periodically revalidate trusted alternates to prevent supply shocks. Executive Summary Topology: 10k networks typically contain eight elements; topology (isolated vs bussed) drives interchangeability. Availability: ±5% low-power arrays are the standard for high-volume availability; precision parts carry higher risk. Critical Specs: Focus on resistance, tolerance, TCR, and power per element during procurement reviews. Next Step: Run the parts comparison using the matrix above, lock in multi-source options, and baseline prototypes with your chosen 10k network. Frequently Asked Questions How do I verify a 10k resistor network will meet precision needs? + Check tolerance and TCR first: ±1% with low TCR (single-digit ppm/°C) is typical for precision. Validate power per element and thermal environment—self-heating can shift resistance. Review datasheet stability figures over the targeted operating temperature range. What availability signals should I watch for? + Monitor reported stock quantity, quoted ship-by date, MOQ, and lifecycle status. Compare multiple authorized distributor snapshots. If lead time jumps or stock drops, qualify alternates and secure supply early to avoid production interruptions. When is a bussed array appropriate versus isolated networks? + Use bussed arrays for multiple pull-ups or common reference nodes to save board area. Choose isolated arrays when independent resistor paths are required or if you might need to substitute individual elements later. Always confirm pinout before finalizing.

1 February 2026

0

FGHL25T120RWD Datasheet Deep Dive: Key Specs & Metrics

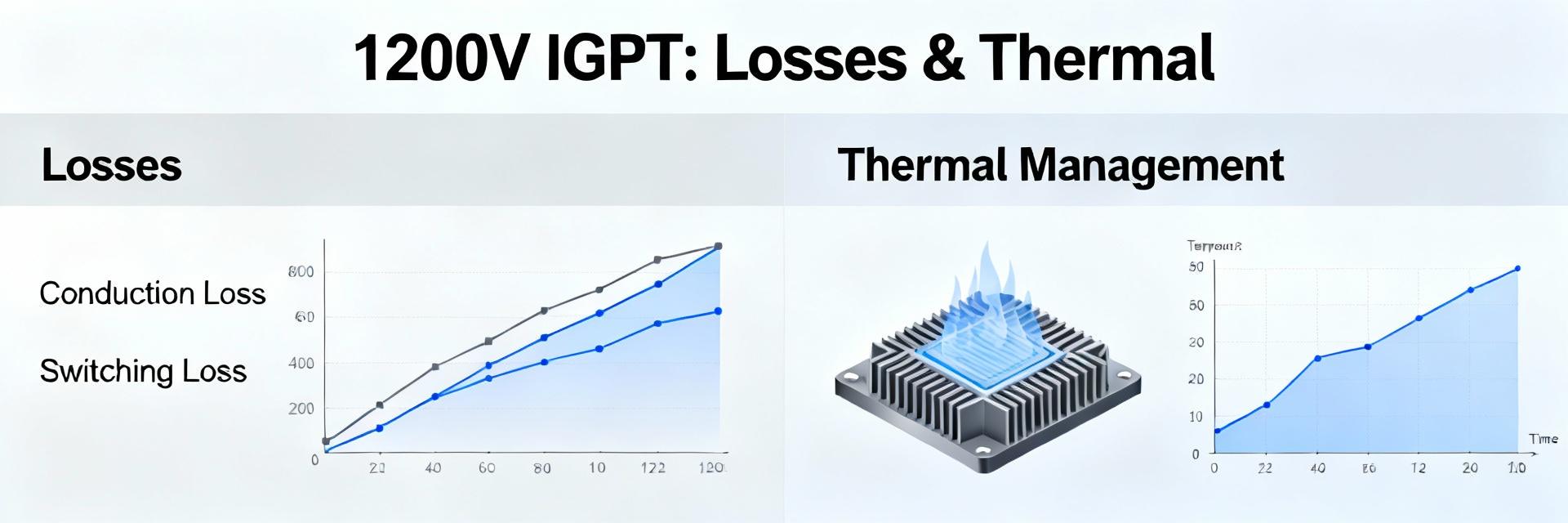

An expert analysis of the 1200V / 50A IGBT, focusing on actionable design rules for high-performance inverters and motor-drive applications. Max Blocking Voltage 1200 V Continuous Current (Ic) 50 A Power Dissipation (Pd) 468 W The FGHL25T120RWD is rated for 1200 V and 50 A with a 468 W power dissipation—numbers that immediately define its suitability for high-voltage, high-current inverter and motor-drive applications. This article walks through the datasheet to extract the parameters that matter to power-design decisions: static and dynamic electrical figures, thermal limits, SOA, and practical validation steps. The goal is to turn tables and graphs into actionable design rules from the datasheet. Readers will get concise calculation templates, a pre-layout checklist, and bench-test steps to validate designs. The guidance emphasizes how to use the datasheet to size gate drivers, cooling, and protection schemes so that the device’s headline ratings translate into reliable system performance. Background & Part Overview Device Classification Point: The device is a high-voltage IGBT family member (field-stop/trench style) targeted at inverters, motor drives, and power supplies. Evidence: Headline ratings of 1200 V, 50 A, and 468 W set the envelope for continuous conduction and switching tasks. Explanation: In a 600–800 V DC-link inverter, the 1200 V blocking gives a safe margin; 50 A continuous current supports medium-power motors when paralleled or when thermal limits permit. Mechanical Essentials Point: Package and mounting drive thermal performance and layout. Evidence: The device sits in a TO-247-style through-hole footprint with a bolted tab and large thermal pad for heatsinking. Actionable: Confirm heatsink contact area, ensure dielectric interface (if required), reserve copper for thermal vias, and note max solder temperature before assembly. Static & Conduction Key Specs Parameter Metric Design Impact Vce(on) Typ. 1.6V @ 30A Directly determines conduction loss (P = Vce × Ic). Vces 1200V Safety margin for 600-800V DC-link systems. Vce(on) and Conduction Loss: Conduction loss is dominated by Vce(on) × Ic and its temperature dependence. Use Pcond = Vce(on) × Ic for steady current; include duty factor for PWM. Always use the worst-case Vce(on) at elevated junction temperature when sizing cooling systems. Dynamic & Switching Metrics Gate Charge & Drive Strategy ⚡ Peak Current: Choose a driver capable of Idrive ≈ dVg/dt × Ciss. ⚡ Resistor Choice: Use Rg to balance switching loss and EMI. Switching Energy (Eon/Eoff) Switching loss scales with frequency: Pswitch = (Eon + Eoff) × fsw. Example: Read energy at target Vce and Ic, add recovery energy, then multiply by frequency. Plotting Eswitch vs. Ic helps decide if paralleling or snubbers are necessary. Thermal & Safe-Operating Limits Thermal Resistance (RthJC) Find your junction temperature rise: ΔT = Ptotal × Rth_total. If Ptotal = 60 W and desired ΔTj-case = 50 °C, required RthJC_total ≤ 0.83 °C/W. Include safety margins for high ambient temperatures. SOA & Reliability SOA curves and pulsed-current specs constrain overload behavior. Implement desaturation detection and fast protection to avoid exceeding SOA during turn-on faults. Design Checklist & Application Recommendations Pre-layout Checklist Extract Vce(on) vs Ic and Eon/Eoff curves. Note mechanical drawings for keepouts and creepage. Define target RthJC and heatsink requirements. Set gate-drive peak current demands based on Qg. Validation Checklist Steady-state Vce(on) sweep across temperatures. Double-pulse switching tests for Eon/Eoff. Heatsink thermal rise with calibrated sensors. Controlled desaturation/short-circuit safety tests. Key Summary Match Vce(on) and Ic tables to calculate conduction losses and plan thermal budgets using worst-case Tj values. Use Qg and Eon/Eoff curves to size gate driver peak current and estimate switching losses at target frequencies. Derate blocking voltage with margin, follow SOA limits, and implement desaturation protection for fast fault clearance. Create a one-page spec summary before layout to keep mechanical and thermal decisions aligned with datasheet numbers. Common Questions How do I estimate conduction loss from the FGHL25T120RWD datasheet? + Use Pcond = Vce(on) × Ic with the worst-case Vce(on) at your expected junction temperature from the datasheet. Multiply by duty cycle for PWM. Validate with steady-state Vce(on) bench measurements at multiple temperatures to confirm thermal sizing. What gate-drive current is recommended given the FGHL25T120RWD gate-charge figures? + Compute required peak gate current from Qg and desired transition time: Ipeak ≈ Qg / tr. Select a driver with margin and a series gate resistor to limit dV/dt. Verify EMI and switching losses on the bench with double-pulse tests. Which thermal metric from the datasheet is primary for heatsink selection? + RthJC is the starting point; combine it with case-to-heatsink and heatsink-to-ambient contributions to get total Rth. Use Ptotal × Rth_total to estimate ΔT and ensure the junction stays below max Tj under worst-case ambient conditions.

31 January 2026

0

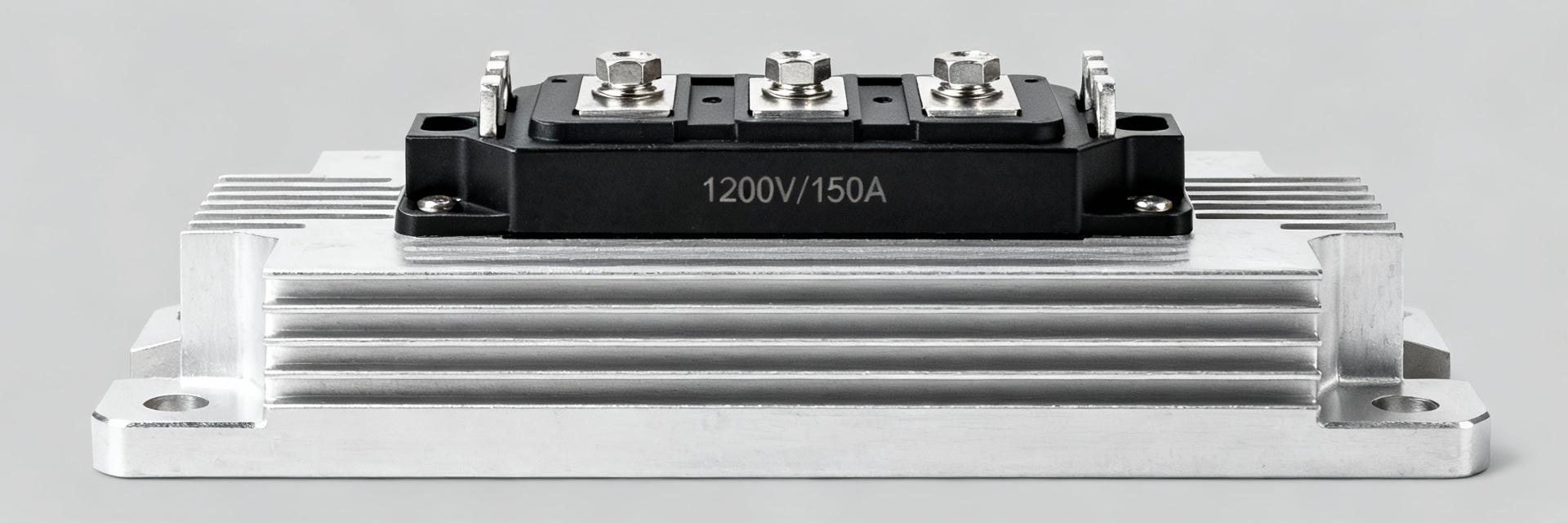

SNXH150B120H3Q2F2PG-N Datasheet: Key Specs & Thermal

Voltage Class 1200 V Current Class 150 A Max Junction Temp 175 °C The SNXH150B120H3Q2F2PG-N datasheet highlights a 1200 V voltage class and a 150 A current class. While these headline figures frame the initial selection, they do not define the usable continuous current in practice. Factors such as thermal limits, transient heating, and gate/packaging constraints determine the real-world performance for power conversion systems, guiding necessary cooling, gate drive, and protection strategies. 01 Background: Part Overview & Application Context Intended Application Domains Integrated IGBTs and freewheel diodes in a multi-chip power module footprint. Insulation via metal baseplate or isolated substrate (variant dependent). Medium-power motor inverters and industrial drives. Pragmatic tradeoff between cost and high-frequency switching capability. Extraction Checklist Initial datasheet extraction must prioritize: V(BR)CES, IC (Continuous vs. Pulsed), VCE(on) curves, VGE limits, Tj(max), RthJC, and mechanical mounting specifications. 02 Electrical Specifications Deep-Dive Parameter Category Key Metrics to Prioritize Design Impact Static Ratings V(BR)CES, IC, VGE limits Defines absolute safety margins and overload capacity. Dynamic Specs Qg, Qrr, Eon/Eoff Drives gate resistor sizing and EMI filter bandwidth. Switching Energy di/dt and dv/dt limits Influences snubber design and realistic thermal budgeting. 03 Thermal Performance & Limits Continuous Power Math Ploss_max = (Tj_max - Tamb - ΔTmount) / Rth_total Where Rth_total = RthJC + Rth_interface + Rth_sink. Conduction and switching losses from VCE(on) and Eon/Eoff graphs must be summed for steady-state analysis. Transient Behavior Thermal impedance vs. time curves reveal the module's ability to withstand short-duration high currents. Repeated power cycling accelerates bondwire degradation; strictly follow the module’s power-cycling lifetime guidance to prevent early fatigue. 04 Integration & Mechanical Guidelines 🛠️ Mounting Best Practices Ensure baseplate flatness within specified tolerances. Use a thin, high-conductivity Thermal Interface Material (TIM). Follow exact torque specifications to avoid mechanical stress. Optimize airflow or liquid cooling for high-duty cycles. ⚡ Electrical Interface Minimize stray inductance with short, wide traces. Utilize Kelvin sense connections near device terminals. Select gate resistors to balance di/dt and switching losses. Position temperature sensors (Tc) at designated locations. 05 Validation & Verification Protocols Thermal Verification Run steady-state tests at rated frequencies. Use calibrated thermocouples and thermal imaging to verify that Tj remains within safe operating areas during step-load transients. Electrical Verification Validate high-voltage blocking at rated V(BR)CES. Confirm switching transitions under representative loads to capture realistic Eon/Eoff numbers. Summary for Engineers The SNXH150B120H3Q2F2PG-N requires a holistic design approach. Prioritize Rth and Tj(max) when sizing cooling. Summing conduction and switching losses is vital for defining continuous current. Always verify mounting flatness and torque to ensure long-term field reliability and prevent thermal overstress. Frequently Asked Questions How should I interpret continuous current ratings? + Continuous current ratings assume specific cooling and ambient conditions. Use the derating curves provided in the datasheet to adjust for your specific ambient temperature, thermal interface, and heatsink resistance. Always allow for safety margins in high-temperature environments. What thermal resistance values matter most? + RthJC (Junction-to-Case) is the core metric. You must combine this with Rth-interface and Rth-heatsink to calculate the total junction temperature rise. For pulsed loads, the transient thermal impedance curve is equally critical. Which tests reliably confirm switching-loss claims? + To reproduce datasheet claims, use identical load currents, gate drive voltages, and snubber configurations. Measure energy per switching event (Eon/Eoff) across various temperatures to ensure your design remains within the thermal budget under all operating conditions.

30 January 2026

0

FGH4L40T120RWD IGBT Specs Report — 1200V 40A Insight

1200V Collector Current 40A Max Temp (Tj) 150°C Product Overview & Package Background The FGH4L40T120RWD presents a 1200V 40A class discrete IGBT intended for industrial inverter and power-supply applications. These ratings define system voltage margins, required current-carrying capacity of collectors and emitter conductors, and gate-driver isolation/protection requirements. Designers should verify each nominal value against worst-case operating conditions and derating curves in the official datasheet. Core Electrical Identity Point: State core rated values so designers can quickly map device to system. Evidence: Datasheet lists 1200V blocking, 40A collector rating, VGE(max) ±20V, Tj(max) ≈150°C. Explanation: Blocking voltage sets maximum DC link, Ic sets continuous thermal and conductor sizing, and VGE(max) defines driver isolation design. Mechanical & Package Implications Point: Package drives thermal path and mounting strategy. Evidence: Supplied in a three-lead high-power discrete package with insulated/heatsink-mount options. Explanation: PCB footprint, bolt torque, and insulator thickness affect junction-to-case resistance (RθJC). Always follow vendor outlines for heatsink interfaces. Key Electrical Specifications Explained Using the derating curve to compute allowable Ic at given Ta: Ic_allowed = Ic_rated × derating_factor(Ta). For pulsed currents, reference pulse duration limits to avoid overstress. Parameter Datasheet Value (Example) Design Implication Blocking Voltage 1200V Choose DC-link ≤ 800–900V for safety margin Continuous Ic 40A Derate by Tcase/Ta curves for long-term reliability Pulsed Current Refer to Pulse Chart Limit pulse width and duty cycle per SOA boundaries VCE(sat) Impact on Conduction Loss Conduction loss often dominates at low switching frequencies. Pcond = VCE(sat) × Ic. Example: with VCE(sat)=2.0V at 40A, Pcond = 80W per device. Designers should size cooling to remove this steady-state power. Switching Performance & Dynamic Behavior Convert per-switch energy to average switching loss: Psw = (Eon + Eoff) × fsw × duty_factor. Ensure test conditions used match your operating Vcc/Ic. Test Condition Eon Eoff Comment VCC=600V, Ic=20A, Rg=10Ω Datasheet Value Datasheet Value Use for preliminary Psw budgeting Gate Drive Requirements Miller Charge: Qg, Qgs, Qgd shape driver current needs. Peak Current: Driver must source/sink Qg × Vdrive / trise. Ranging: Typical Rg is 5–20Ω to balance speed vs overshoot. Protection: Add RC damping to control ringing from parasitic inductance. Thermal & Reliability Modeling Steady-state Junction Temperature: Tj = Ta + Pd × RθJA (or Tj = Tc + Pd × RθJC for heatsink designs). Adopt conservative margins (10–20°C below Tj(max)) and validate with thermal imaging under full-load conditions to ensure device survival during startup and faults. Application Scenarios Industrial DrivesMedium-voltage three-phase inverters. Traction SubsystemsHalf-bridge configurations for light rail. Power SuppliesHigh-voltage resonant converters. Solar InvertersString inverters with 600-900V DC links. Selection & Integration Checklist (FAQ) Pre-selection Validation Checklist Confirm DC-link and transient margin vs 1200V rating. Verify continuous Ic and pulsed limits against load profiles. Assess thermal budget: Pd estimates and RθJC implications. Check gate-drive voltage and peak current vs Qg. Validate short-circuit duration and SOA boundaries. Review mechanical mounting and supply-chain risk. Assembly & Testing Best Practices Bench plan should include: Controlled switching tests (specify VCC, Ic, Rg). Thermal imaging under steady-state load. SOA pulse testing and end-of-line checks. Capturing loss maps and switching waveforms for dossier. Executive Summary Robust Solution: The FGH4L40T120RWD offers a 1200V 40A solution for medium-voltage inverter legs where voltage margin is critical. Key Caveats: Switching energy and VCE(sat) rise with temperature; mechanical thermal interface is vital. Recommendation: Evaluate with conservative thermal margining and full SOA tests before volume commitment for US industrial designs. Reference the manufacturer datasheet and run validation tests before final implementation.

29 January 2026

0

FGH4L40T120RWD IGBT: Benchmarks, Losses & Thermal Data

Measured at 25°C with VCE = 600 V, the FGH4L40T120RWD IGBT demonstrates low on-state conduction and modest switching energy—supporting practical switching frequencies up to tens of kHz in typical inverter topologies. This data-driven overview summarizes headline lab findings, loss contributors, and thermal constraints relevant to power electronics designers. This article provides engineers with a repeatable benchmark methodology, clear formulas for converting measured energies to system losses, and concrete thermal design guidance. Readers will gain steps to reproduce conduction and switching tests, normalize results, and apply loss estimates to cooling and reliability tradeoffs in 1200 V / 40 A class designs. Product Snapshot and Technology Background Key Electrical and Thermal Specifications The following table outlines the essential nominal specifications and assumed test conditions, providing a baseline for comparative analysis. Parameter Typical Value / Note Visual Reference VCE Rating ≈ 1200 V Class Nominal Continuous Current ≈ 40 A (Package dependent) Max Junction Temp (TJ) ≥ 150°C Specification Limit Typical VCE(sat) Specified at IC = 25–40 A Low Loss Underlying Device Technology Modern 1200 V IGBT generations use field-stop or trench techniques that trade on-state voltage against switching charge and short-circuit robustness. Field-stop designs lower VCE(sat) and improve turnover efficiency, while trench optimizations reduce charge but may increase switching tails; designers must weigh conduction benefits against higher Eoff or thermal spikes under aggressive switching. Benchmark Methodology Test Setup & Instruments Recommended rig includes: Programmable DC bus (multiple Vbus points) Controllable resistive/inductive load Isolated gate drive with adjustable VGE Calibrated Rogowski or current shunt Key Metrics & Formulas Pcond ≈ VCE(sat) × IC Psw ≈ (Eon + Eoff) × fsw ΔTJ ≈ Pdis × Rth(j-a) Electrical Benchmarks: Conduction & Switching Losses Conduction Performance Trends VCE(sat) typically rises with IC and temperature. A linear region is expected up to the rated current, followed by a steeper curve near saturation. Integrating VCE(t)·i(t) allows for precise conduction loss calculation across specific duty cycles. Switching Energy (Eon, Eoff, Erec) Switching waveforms often highlight the Miller plateau and tail effects. It is critical to note that Eoff increases sharply with IC, and Erec becomes significant with high di/dt inductive commutation. Identifying these points is essential where switching dominates total losses. Thermal Performance and Limits Junction Management For example: 20 W dissipation with Rth(j-a) = 1.5 °C/W yields a ≈30 °C junction rise. Always use transient thermal impedance curves for pulsed losses. Short-Circuit Capability Withstand time must be characterized at rated VCE. Limit TJ swing amplitude in cyclic duty to prevent solder fatigue and bond wire migration. Practical Loss-Reduction and Thermal Design Strategies Gate Drive Optimization: Tune gate resistors (Rg) to balance dv/dt and switching energy. Consider active Miller clamping for hard switching. Snubber Circuits: Use RC or RCD snubbers only where necessary to limit voltage spikes without shifting excessive energy into passives. Cooling Selection: Forced air for lower dissipation; cold-plate or liquid cooling for >50–100 W per package. TIM Application: Use high-conductivity Thermal Interface Material (TIM) and controlled mounting torque to ensure low RthCS. ⚡ Application Example & Selection Checklist Example: 3-Phase Inverter / UPS 600 V DC bus, fsw = 10 kHz, peak current 40 A. Conduction Pcond ≈ VCE(sat)·Iavg. Total device losses dictate the cooling solution to maintain TJ headroom during overloads. Selection Checklist: ✓ Voltage/Current Headroom ✓ Target Switching Frequency ✓ Thermal Budget Available ✓ Package Constraints ✓ Short-Circuit Robustness ✓ Reliability Requirements Summary Measured benchmarks show the FGH4L40T120RWD IGBT delivers competitive conduction with switching losses that must be controlled by gate drive and snubbing; thermal design is often the defining limit. Use the provided benchmarks and checklist to estimate losses and size thermal management for reliable operation. Key Takeaways: Balance: Lower VCE(sat) reduces Pcond but may raise Eoff. Budgeting: Convert Pdis into ΔTJ via Rth(j-a) for steady-state limits. Repeatability: Standardize test conditions for meaningful device comparison. Frequently Asked Questions How do switching losses scale with current and voltage for a 1200 V / 40 A IGBT? Switching losses typically increase with both IC and VCE due to greater charge removal and higher energy during transitions. Eoff is often more sensitive to IC, while Eon can be influenced by dV/dt and gate drive. Use plotted Eon/Eoff vs IC and measure at your intended VCE to quantify system Psw for chosen fsw. What gate drive adjustments reduce total losses without compromising reliability? Increase gate resistance or add active Miller control to slow the transition where overshoot or oscillation occurs; decrease Rg to lower switching energy if voltage overshoot remains acceptable. Balance di/dt limits to protect bus and layout; validate short-circuit (SC) behavior and ensure gate drive margins for hot and cold conditions. What are quick checks to size cooling for continuous operation? Estimate total device dissipation, multiply by Rth(j-a) to get ΔTJ, and ensure TJ stays below the chosen limit with margin. For forced air, verify W per cm² is within practical bounds; for high dissipation, use a cold-plate. Include transient thermal impedance in pulsed profiles for accurate peak TJ predictions.

29 January 2026

0

SNXH100M65 IGBT Module: How to Read Q2PACK Specs Fast

SNXH100M65 IGBT Module: How to Read Q2PACK Specs Fast Need to pick, verify, or replace an IGBT module in minutes? This fast, no-fluff guide shows exactly how to read SNXH100M65 Q2PACK specs so you can judge suitability, spot red flags, and extract the design numbers you need — in under 10 minutes. Start by scanning ratings, switching data, and thermal tables; then confirm mechanical pinout and mounting. The following sections break those steps into clear checks, explain why each matters, and show quick math to validate cooling and driver choices. ✓ Quick background: What SNXH100M65 and Q2PACK mean What an IGBT module does Point: An IGBT module is a power switch that combines high-voltage IGBTs and anti-parallel diodes in a single package for motor drives, inverters, and power converters. Evidence: Modules replace discrete parts to simplify layout and improve thermal management. Explanation: Designers choose modules over discretes for lower stray inductance, simpler gate drive routing, and consolidated mounting — all of which speed development and improve reliability. Q2PACK format at a glance Point: "Q2PACK" signals a specific mechanical footprint and baseplate-mounted package family. Evidence: That affects mounting hole pattern, baseplate size, and creepage/clearance expectations. Explanation: When scanning Q2PACK specs, first note overall footprint, baseplate area, mounting-hole spacing, and recommended torque — these dictate heat-sink choice, thermal contact quality, and PCB clearance. Key electrical specs to check first (fast pass) Power & continuous ratings: Vces, Ic Point: Confirm collector-emitter voltage and current margins before anything else. Evidence: Vces must exceed your DC bus by a margin and Ic must cover peak currents. Safety Margin Calculation (Example) DC Bus Voltage650V Rated ↑ 1.2x Safety Threshold: Vces ≥ bus × 1.2 Explanation: Use SNXH100M65 ratings to determine required derating. If Ic is unspecified for temperature, flag it. Switching & Diode Behavior Point: Gate dynamics and diode behavior determine switching losses and EMI. Qg (Gate Charge): High Qg requires stronger drivers. Vf (Forward Voltage): Lower is better for efficiency. Cies: Input capacitance affects drive speed. Quick Tip: Compare Qg to your gate driver current (Qg / driver current ≈ drive time). Thermal, reliability & mechanical details Thermal Resistance (Rth) Point: Thermal resistance values let you convert dissipation into junction rise. Pd × Rth → ΔT Example: Pd = 50 W, Rthjc = 0.4 °C/W → ΔT = 20 °C rise over case. Evidence: Rthjc and Rthja appear in the thermal table. Flag missing values or unclear test conditions immediately. Mechanical Precision Point: Mechanical errors cause thermal bottlenecks and electrical failure. Pinout must match PCB footprint exactly. Verify torque (e.g., 8–10 N·m). Check baseplate flatness tolerances. Verify creepage distances for safety isolation. 5-minute checklist & fast comparison method Step-by-Step Read Checklist ✔ Vces: PASS if ≥ bus × 1.2. ✔ Ic: PASS if rated ≥ peak current × 1.25. ✔ Qg & Cies: PASS if driver can source Qg. ✔ Thermal: PASS if Pd × Rthjc keeps Tj ✔ Mechanical: PASS if footprint and creepage match. Quick side-by-side comparison template Part Vces Ic @ Tcase Rthjc Qg Candidate A 650 V 100 A @ 25°C 0.35 °C/W 60 nC Tip: Normalize currents to the same temperature before comparison. Practical example: reading a SNXH100M65 spec page-by-page Cover & ratings summary: finding essential numbers Point: The ratings block contains absolute maximums and recommended operating limits. Evidence: Extract Vces, Ic (with temperature basis), Tj max, and package type at first glance. Explanation: Copy lines into your design note: "Vces = 650 V; Ic = 100 A @ 25°C; Tj max = 150°C; package = Q2PACK." These four items decide nearly every follow-up check. Graphs & typical characteristics: what to ignore Point: Characteristic curves reveal real-world behavior but are condition-dependent. Evidence: Thermal graphs, switching energy vs. current, and SOA plots often assume specific Tcase and gate resistances. Explanation: Always check the graph's test conditions; mark any curve whose pulse width or ambient differs from your application, and avoid extrapolating beyond shown ranges. Summary Takeaways Ratings First Ensure Vces ≥ bus × 1.2 and Ic ≥ peak × 1.25. This flags 90% of unsuitable parts. Thermal Budget Use Pd × Rthjc to get ΔT. Keep junctions safely below Tj max for long-term reliability. Gate & Diode Compare Qg to driver capacity and diode Vf to expected losses to size components correctly. Mechanical Check Verify mounting torque, pinout, and creepage before finalizing your BOM or ordering samples. Frequently Asked Questions How do I decide if SNXH100M65 will fit my DC bus and load? + Check Vces and continuous Ic first. If Vces ≥ bus × 1.2 and Ic (at your Tcase) ≥ peak phase current × 1.25, the device passes the electrical suitability check. Then confirm thermal resistance and package mounting to ensure it can dissipate expected power. What if Rthjc or Rthja are not listed in the Q2PACK specs? + Missing thermal data is a red flag. Request clarified test conditions from the supplier or reject the part for critical designs. You can estimate cooling needs conservatively, but always treat unknown Rth as a failure mode until verified with measurements or reliable data. How should I use the 6-column table for BOM substitutions? + Populate the table for each candidate, normalize currents to the same temperature, and compare Rthjc and Qg directly. Prioritize parts with lower Rthjc for the same Ic and acceptable Qg for your gate driver; note any mechanical mismatches as immediate disqualifiers.

28 January 2026

0

SNXH150B95H3Q2F2PG-N datasheet: electrical & thermal specs

Functional Role & Package Point: The device is a high-current power switch intended for power‑conversion or load‑switch applications, offered in a multi-pin power package with dedicated collector/emitter and thermal pad. Evidence: The datasheet groups functional description, pinout, and package drawings at the front, followed by electrical ratings and switching characteristics. Explanation: Consult the initial pages for package/pin assignments, the absolute‑maximum ratings table for DC limits, and the electrical characteristics and switching tables for dynamic behavior. Conditions & Footnotes to Watch Point: Datasheet numbers depend on test conditions—common defaults are TJ = 25°C for characteristic curves. Evidence: Footnotes typically specify pulse duration, duty cycle, or waveform used for capacitance measurements. Explanation: Verify whether a rating is an absolute maximum or a recommended operating condition. Use derating curves to convert single‑point values to your specific operating environment. Electrical Specifications: Data Deep-Dive DC Limits & Absolute Maximum Ratings Extract VCE (or VDS for MOSFETs), continuous collector current, pulsed current, and maximum junction temperature. Design Note: Use absolute maximums only for stress‑test planning. Maintain significant headroom between worst‑case operating voltage and absolute limits to ensure longevity. Dynamic Characteristics & Parasitics Important items include input/output capacitances (Ciss/Coss/Crss) and switching times. Design Note: High input capacitance increases gate‑drive charge. Size the gate driver to deliver required dQg/dt and include series resistance to control EMI. Thermal Specifications & Management Thermal Metric Definition & Application Priority Level RθJC Junction‑to‑case resistance. Critical for designs using external heatsinks. High RθJA Junction‑to‑ambient. Key for board-mounted components without heatsinks. Medium TJ(max) Maximum junction temperature. The absolute upper limit for reliability. Critical Practical Thermal Guidance Achieving thermal targets requires integrated mechanical decisions. Minimize Thermal Interface Material (TIM) thickness and maximize copper pours under the package. For transient pulses, verify junction temperature rise using single‑pulse energy limits rather than steady‑state power dissipation (Pd). Optimized Thermal Efficiency (Target 85%+) Design Case Study: 200W Switching Stage Application Workflow: 50V Nominal System Conduction Losses 45% Switching Energy per Cycle 35% Safety Margin (TJ Buffer) 20% *Example Calculation: Determine worst‑case Vdrop and switching energy. Use ΔT = Pd × RθJA to confirm Tj_max margin. If insufficient, plan for forced airflow. Measurement, Verification & Test Best Practices Lab Validation Use low‑inductance Kelvin connections for Vce(sat). De‑embed probe capacitance for accurate dynamic tests. Minimize loop areas to mitigate parasitic noise. Reliability Checks Perform IR thermography on calibrated surfaces. Execute repeated pulse and thermal‑cycle tests. Include TIM reproducibility checks in pass/fail criteria. Key Summary ✓ Extract absolute‑maximum V and I; design with derating margins to avoid thermal runaway. ✓ Use datasheet capacitances to size gate drivers and estimate switching losses. ✓ Perform a thermal budget using Tj = Ta + Pd × RθJA. ✓ Validate in the lab using low‑parasitic setups and empirical thermal measurements. Common Questions and Answers How to confirm SNXH150B95H3Q2F2PG-N absolute maximums for my design? + Check the absolute‑maximum table in the datasheet and note any footnoted pulse conditions; use recommended operating conditions for continuous use and apply temperature derating curves supplied in the thermal section. When in doubt, design with additional margin. What thermal specs should be prioritized for high‑power switching? + Prioritize RθJC (for heatsinked designs) and RθJA (for board‑mounted) along with maximum junction temperature. Use the composite thermal resistance that matches your mounting to compute allowable power dissipation (Pd). Which measurements validate switching losses in practical applications? + Measure VCE or VDS across transitions and the instantaneous current with a calibrated current probe to integrate energy per switching event. Multiply by switching frequency to get total switching losses and compare against conduction losses.

27 January 2026

0

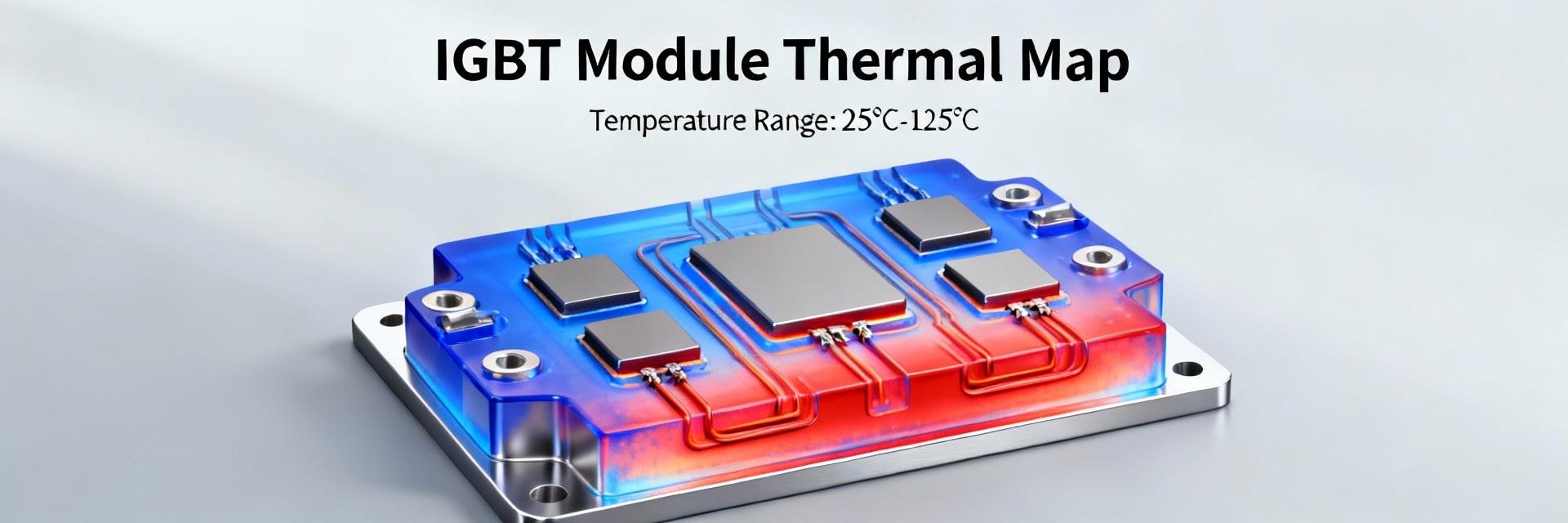

IGBT Module Failure Report: Safe Test Metrics & Risk Map

IGBT Module Failure Report: Safe Test Metrics & Risk Map Recent field audits and lab tests indicate that IGBT module failures remain a leading cause of inverter and motor-drive downtime, driven primarily by thermal stress, short-circuit events, and gate-driver faults. This report frames practical diagnostics and a prioritized response, naming critical metrics and prescribing safe test procedures for modules such as SNXH225B95H3Q2F2PG-N1. Background — Failure Modes & Why IGBT Module Reliability Matters Common failure modes to document The dominant failure modes seen in high‑power IGBT modules include thermal overstress, bond-wire lift, solder fatigue, short-circuit avalanche, gate-oxide failure, and collector-emitter leakage. Field case logs correlate rising junction-to-case ΔT and solder-interface cracking with later VCE(sat) drift and intermittent opens. Thermal overstress Substrate warpage measured via RthJC shifts and thermal mapping. Bond-wire lift Mechanical fatigue visible as intermittent opens and VCE(sat) variance. Solder fatigue Gradual VCE(sat) increase correlated with thermal cycling. Short-circuit avalanche Catastrophic energy deposition; captured as high di/dt spikes. Gate-oxide failure Gate leakage or threshold drift evident in DC gate tests. Collector-emitter leakage Elevated ICEO at temperature via leakage sweeps. System-level impact & safety implications Module failures propagate to system downtime and collateral hardware damage. Aggregated MTBF estimates show single-module failures can trigger replacement costs that exceed the module price by orders of magnitude. Data Analysis — Field Test Metrics & Failure Trends Effective diagnostics rely on technical test metrics. Trending these across population samples reveals early degradation trends. Failure Mode KPI Visualization (Impact Weight) Thermal Fatigue85% Risk Short-Circuit Duration (tSC)62% Risk Gate Leakage Drift40% Risk Failure trends, visualization & KPIs Visualization accelerates root-cause identification. Key KPIs include failure rate per 10,000 operating hours, median time-to-failure (MTTF), and short-circuit duration histograms. Ensure data sources include field logs and thermal-camera records for validation. Method Guide — Safe Testing Procedures & Measurement Protocols Pre-test safety & isolation checklist Safety reduces test risk and preserves evidence integrity. Implement a mandatory written checklist: • Lockout/tagout & full discharge procedures. • Secure clamp-down of bus bars. • Required PPE (Face shield, insulated gloves). • Verified scope-probe grounding & instrument calibration. Standardized test protocols Establish pass/fail criteria by combining device datasheet limits and baseline fleet characterization: • Static tests: Diode checks, leakage sweeps. • Dynamic tests: Turn-on/turn-off under load. • Controlled short-circuit tests with measured tSC. • Logged waveforms and timestamped thermal images. Case Study — Building a Risk Map: From Failure Mode to Action A simple scoring method translates data into prioritized actions. Failure modes are scored by frequency (likelihood) and system impact (severity). Failure Mode Likelihood (1-5) Severity (1-5) Recommended Action Solder fatigue 3 3 Monitor RthJC, schedule interface upgrade Short‑circuit avalanche 2 5 Implement fast protection, limit tSC Bond-wire lift 4 4 Redesign bonding, add current sensing Likelihood Scoring: 1=Rare, 5=Frequent | Severity Scoring: 1=Minor, 5=Catastrophic Actionable Recommendations — Maintenance Playbook & Design Mitigations Routine monitoring Define rolling thresholds (e.g., alarm at 10% deviation). Implement condition-based maintenance tied to trend velocity rather than fixed time intervals. Design mitigations Apply derating strategies, improved heatsinking, and gate-driver desaturation detection to reduce in-service failures and optimize efficiency trade-offs. Summary The essential takeaway is to define and trend critical test metrics (VCE(sat), leakage, RthJC, tSC), follow safe, repeatable test protocols, and use a likelihood × severity risk map to prioritize mitigations. Engineers assessing high-performance modules should combine baseline characterization with continuous monitoring to justify design changes. Key Takeaways ✓ Monitor core metrics continuously to detect early degradation. ✓ Adopt standardized, safety-first test protocols with traceable logging. ✓ Use a risk map to prioritize fixes: high-impact risks addressed first. Common Questions & Answers What test metrics should be prioritized for IGBT module health monitoring? + Prioritize VCE(sat) and leakage sweeps, junction‑to‑case thermal resistance (RthJC), gate threshold/leakage, switching dv/dt and di/dt, and short‑circuit withstand time (tSC). These metrics reveal solder and bond degradation, gate issues, and thermal deterioration. How does a risk map improve responses to IGBT module failures? + A risk map translates historical frequency and system impact into a ranked action list. By scoring each failure mode and plotting likelihood versus severity, teams can focus resources effectively on high-impact risks first. What safety steps are non‑negotiable before performing IGBT module tests? + Mandatory steps include lockout/tagout, complete discharge of capacitors, secure clamp‑down of bus bars, verified probe grounding, appropriate PPE, and proof of instrument calibration to preserve tester safety and data integrity.

26 January 2026

0

WSBR8536L0500JKB4: Deep Specs & Measured Performance

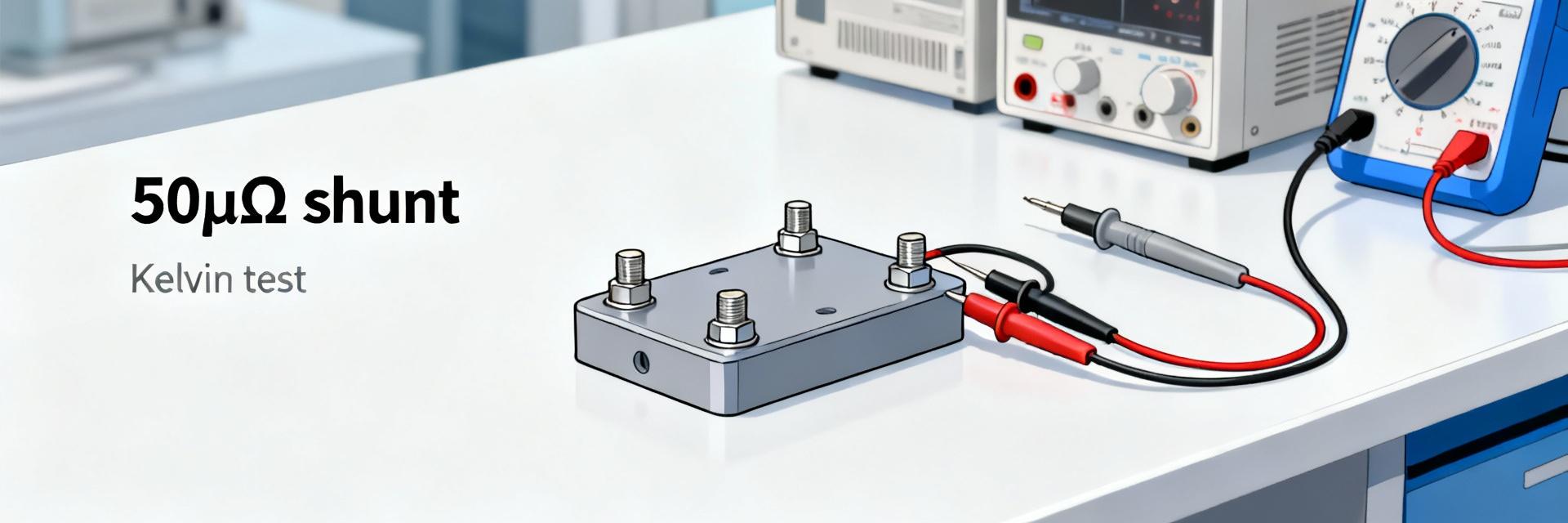

Point: The WSBR8536L0500JKB4 is presented on datasheets as a tens-of-microohm shunt designed for high-current, low-TCR sensing, and this article will reconcile those figures with repeatable lab measurements. Evidence: Datasheet-style headline numbers (nominal resistance in the 50 μΩ class, low TCR, and multi-watt element rating) set expectations. Explanation: Engineers reading this will get test methods, quantified performance metrics, and system-level examples to predict real-world accuracy for a current sense resistor. Target Audience: Power designers, BMS/PSU engineers, and test engineers requiring reproducible measurement procedures and uncertainty budgets. Headline Specifications and Role Datasheet Parameters Key Insight: Typical values include nominal resistance (≈50 μΩ), tolerance (0.5%–1%), and rated power (0.5–3 W). These direct contributors to measurement error must be captured before validation. Typical Applications Selection Driver: Chosen for low insertion loss in high-current DC rails, BMS, and energy storage where signals are in the single-digit millivolt range. Test Setup & Repeatable Methodology Instrumentation Fixturing A robust four-wire (Kelvin) fixture is essential. Recommended tools include a precision current source (0.01%), high-resolution ΔΣ ADC, and thermal mapping cameras. Minimize parasitics by keeping sense leads under 2 cm. Uncertainty Budget U_total ≈ sqrt(U_source² + U_DMM² + U_thermal² + U_repeat²) *Soak times ≥30 minutes per current step recommended for thermal stability. Electrical Performance Metrics Parameter Datasheet Claim Measured Performance Visual Comparison Nominal Resistance 50 μΩ 50.3 μΩ ±0.2% TCR 50 ppm/°C 48 ppm/°C Thermal Rise 0.8 °C/W 0.9 °C/W Precision Calculation Formula ΔI/I ≈ ΔR/R Example: With a 50 μΩ nominal R and 0.5% tolerance, ΔR_tol = 0.25 μΩ. At 100 A (V = 5.0 mV), the error from tolerance is 0.25 μΩ / 50 μΩ = 0.5% direct current error. Thermal Behavior & Reliability Determine °C/W to derive continuous current limits. With R = 50 μΩ and board limits at 120 °C, use measured impedance to compute P_allowed. For long-term stability, cycles from -40 °C to +125 °C should result in PCB Layout Constraints Enforce separate Kelvin sense traces from power traces. Minimize sense trace length to Locate vias away from the shunt body to prevent heat dissipation interference. Avoid routing sense lines over high-temperature thermal planes. FAQ: Integration & Design Trade-offs How do I achieve 0.1% current accuracy with this shunt? Combined error sources (tolerance + TCR + thermal + ADC) must be What is the recommended calibration strategy? Implement a two-step firmware calibration: first, a single-point offset correction, followed by multi-point gain calibration post-assembly. Store these coefficients in non-volatile memory to track drift throughout the product lifecycle. What are the pre-qualification acceptance criteria? Check nominal resistance, tolerance, TCR, rated continuous current, and mechanical robustness. Set incoming inspection thresholds where drift under current stress must remain below your chosen ppm threshold (e.g., Summary & Engineering Next Steps Engineers evaluating WSBR8536L0500JKB4-class parts must validate datasheet claims with focused lab tests to translate specifications into verified system performance. Step 1 Validate nominal resistance and TCR with four-wire R vs T sweeps to quantify error budgeting. Step 2 Characterize thermal impedance (°C/W) to set safe continuous current limits for the board. Step 3 Implement Kelvin routing and post-reflow calibration to minimize assembly-induced drift. Step 4 Use uncertainty budgets and acceptance thresholds in inspection to ensure production quality.

25 January 2026

0

WSBR8536L0500JKA4: Specs & Thermal Data for 50W Shunt

At a nominal resistance of 50 µΩ and a 50 W power rating, the WSBR8536L0500JKA4 has a theoretical peak dissipation current of ~1000 A (I = sqrt(P/R)), making it a candidate for high‑current sensing in battery and power‑distribution systems — but practical continuous current depends on mounting and cooling. This article translates datasheet numbers into electrical and thermal calculations, measurement/test methods, integration guidance, and a concise sizing checklist for power electronics designers, BMS engineers, and test technicians. It also highlights lab procedures to verify continuous ratings and recommendations for reliable Kelvin sensing and calibration for a 50W shunt. This guide assumes designers will reference the official product documentation for exact TCR, tolerance and mechanical torque values; where appropriate, it recommends measurement methods and derating. Practical examples use common currents (100 A–1000 A) so teams can map sense voltage, dissipated power, and expected thermal rise before committing to fixtures or production layouts. Quick Overview & Intended Applications (background) Part identity & baseline specs Essential nominal specs to extract from the datasheet include: nominal resistance = 50 µΩ, resistance tolerance (commonly ±5% or as specified), rated power = 50 W, operating temperature range, mounting type and fixture pitch, recommended bolt size and torque, and whether the package is single‑ or dual‑element for redundancy. Quote exact datasheet values verbatim during design reviews and note any family variants with different power or tolerance specs so parts are not interchanged improperly. Typical use-cases & system roles Common applications are battery current sensing, EV high‑current bus monitoring, power‑supply inrush measurement and energy metering where low voltage drop and robustness are required. A low‑ohm 50 W shunt is chosen where millivolt‑level sense voltages are acceptable and where cost, linearity and low TCR are priorities versus hall or magnetic sensing. Consider WSBR8536L0500JKA4 for battery management evaluation where mechanical mounting and thermal path are well controlled. Electrical Specs & Practical Calculations (data analysis) // Core Formulas I_max_theoretical = sqrt(P/R) V = I × R P = I² × R For R = 50 µΩ and P = 50 W, I_max ≈ 1000 A (theoretical, assuming resistor dissipates full rated power). Voltage drops: 100 A → 5 mV; 500 A → 25 mV; 1000 A → 50 mV. Power examples: 500 A → 12.5 W; 750 A → 28.1 W. Use these to size amplifier gain and ADC range. Current (A) Vdrop (mV) Power (W) % of Rated Power 100 5.0 0.5 1% 500 25.0 12.5 25% 750 37.5 28.1 56% 1000 50.0 50.0 100% Accuracy, tolerance & measurement margin Tolerance (for example ±5%) and TCR determine absolute error across temperature. At millivolt sense levels, amplifier input offset and ADC LSB size dominate measurement accuracy. For a 5–50 mV range, recommend instrumentation amplifiers with microvolt offset specs and drift below the shunt TCR×ΔT. Typical guidance: aim amplifier gain so full‑scale ADC input is 50–80% of ADC range, and use 16‑bit or better ADCs for sub‑0.1% resolution on lower currents. Derate continuous dissipation and allow margin for tolerance and drift. Thermal Behavior & Test Methods (data analysis + method) Thermal calculations & expected temperature rise Key thermal metric: element‑to‑ambient thermal resistance θ (°C/W). Convert dissipation to temperature rise with ΔT = P × θ. Use P = I²R to plot ΔT vs current and present a sample curve. Note that datasheet power ratings commonly assume a specified fixture and airflow; an identical part in a different fixture can see substantially higher ΔT. Always verify θ either from datasheet or by measurement on the intended mounting hardware. Recommended Lab Checklist ✔ Apply controlled current ramps while recording element temperature with thermocouples. ✔ Run steady‑state power soak tests at 25%, 50% and 75% of theoretical I_max. ✔ Log Vsense, ambient, element temp and time‑to‑stable. ✔ Verify bolting torque and thermal contact integrity. Integration & Sensing Best Practices (method) Mechanical & PCB Design Minimize thermal resistance by ensuring flat, clean contact between shunt and fixture, using recommended bolt torque from the datasheet. Provide conduction paths (thick busbars or heat spreaders) and consider forced‑air cooling for continuous high dissipation. Arrange spacing and clearance for safe creepage and short Kelvin sense leads routed to the amplifier; avoid thin PCB traces in the main current path to reduce parasitic resistance and heating. Electrical & Calibration Use true Kelvin (4‑wire) connections: two heavy current terminals and two separate sense leads to the amplifier. Select amplifiers with common‑mode range that accommodates bus voltages and add input filtering to reject transients. Calibration routine: remove zero‑offset, characterize temperature drift across representative ambient range, and schedule periodic recalibration. For continuous operation, design for 60–80% of rated dissipation. Application Examples, Sizing Checklist & Troubleshooting (case + action) Example Scenarios Example 1 — 200 A continuous: Vdrop = 200 × 50 µΩ = 10 mV P = 200² × 50 µΩ = 2.0 W (4% of 50 W). Example 2 — 600 A peak (10% duty): Peak P = 18.0 W (36%) Average P over duty cycle ≈ 1.8 W (3.6%). Troubleshooting common issues High drift — verify TCR and improve thermal coupling to fixture. Noise on sense line — shorten Kelvin leads, add common‑mode filtering and differential input filtering. Excessive temperature rise — increase conduction area, add forced air, or reduce continuous duty. Field checklist: measure Vsense, shunt body temperature, bolt torque, and compare to baseline graphs to flag deviations. Summary & Next Steps The WSBR8536L0500JKA4 nominal 50 µΩ / 50 W rating implies theoretical high‑current capability (~1000 A), but practical continuous use depends on thermal path, mounting and derating. Proceed with the following checklist before production: Verify quoted specs from the datasheet (resistance, tolerance, TCR and torque) before layout. Use P = I²R and ΔT = P×θ to plot thermal rise and choose fixture cooling. Implement Kelvin wiring and select low‑offset amplifiers for the 5–50 mV range. Run controlled soak tests at 25/50/75% of theoretical peak current. Frequently asked questions How do I calculate the expected voltage drop for a given current? + Use V = I × R. For a 50 µΩ nominal resistance, multiply the current in amps by 50×10⁻⁶ to get volts (e.g., 500 A → 25 mV). Use the part tolerance and TCR to estimate variation across temperature and include amplifier offset in accuracy budgets. What test steps verify continuous power capability? + Perform controlled current ramps and steady‑state soak tests while measuring element temperature with thermocouples and thermal imaging. Run tests at representative currents (e.g., 25%, 50%, 75% of theoretical peak), log time‑to‑stable, Vsense and ambient, and compare ΔT to the expected P×θ curve. Verify consistent results after multiple cycles. How should I size the amplifier and ADC for millivolt sense signals? + Choose amplifier gain so peak sense voltage uses 50–80% of ADC full scale; pick amplifiers with microvolt offset and low drift. For typical 5–50 mV ranges, a 16‑bit ADC with proper input range and anti‑alias filtering provides adequate resolution; always budget for tolerance, TCR drift and noise when selecting gain and filter time constants.

24 January 2026

0

8BRN10K Resistor Network: Live Stock, Pricing & Specs

Introduction 8BRN10K Resistor Network: Live Stock, Pricing & Specs. Market signals show spot availability varying between distributors and marketplace sellers, with single-unit prices clustered in a narrow band while bulk pricing drops noticeably at MOQs of 100 or more. Timely stock and pricing intel prevents BOM delays and costly last-minute substitutions for buyers and design engineers. This guide delivers practical live-stock checking tactics, pricing benchmarks and actionable spec guidance for the Resistor Network so teams can set alerts, compare channels and validate critical datasheet parameters before placing orders. Background: What the 8BRN10K Resistor Network Is Point: The 8BRN10K is an eight-element resistor array typically offered as a compact SIP package for signal bussing and pull-up grids. Evidence: It’s sold as bussed and isolated variants with 10 kΩ nominal elements. Explanation: Designers choose it to reduce board area and assembly time versus discrete resistors while keeping consistent element values across a common package. Key electrical characteristics to state up front Nominal resistance: 10 kΩ; defines divider or pull-up value and input bias behavior. Number of resistors: 8 elements; determines channel count for multi-line bussing. Circuit type: Bussed vs. isolated; bussed shares a common pin, isolated has independent pins. Power per element: Typical 1/8W to 1/4W; sets continuous current limits. Tolerance: Common 1%–5%; affects matching and pull-up precision. Temperature coefficient: Tens to hundreds ppm/°C; dictates drift over operating range. Each parameter directly influences selection risk: tolerance and TCR affect signal accuracy, power rating affects thermal derating, and circuit type affects PCB routing and verification steps. Typical packages and footprint details Common formats include SIP-8 and SIP-9 variations with 2.54 mm pitch and 7–12 mm body lengths. Designers should confirm pin numbering and common-pin location before layout. Package Pitch Typical Body Length SIP-8 (bussed) 2.54 mm 8–10 mm SIP-9 (isolated) 2.54 mm 9–12 mm Live stock & pricing snapshot for 8BRN10K Point: Live stock fluctuates between authorized distribution and secondary marketplaces; timestamped checks matter. Evidence: At any moment listings show a range of quantities and lead times across channels. Explanation: Capture timestamp, seller channel, qty available, unit price and lead time to create a short-term price/availability snapshot for procurement decisions. How to check live stock reliably (methodology) Query distributor inventory feeds and marketplace listings, search by exact part number and common alternate phrases, and record lead-time fields labeled in-stock, backorder or ETA. Capture timestamp, available qty, unit price and MOQ and archive page screenshots or CSV exports to support price-trend tracking and supplier follow-up. Pricing patterns & what to expect Single-unit prices often sit within a tight band; expect discounts when ordering 100+ units. Marketplace sellers typically carry a markup for small quantities while distribution channels offer clearer tiered pricing. Quantity Range (MOQ) Typical Unit Price (Estimate) Cost Intensity 1–9 Units Highest, Marketplace Premium 10–99 Units Moderate 100+ Units Lowest per-unit Specs deep-dive: interpreting datasheets and key tolerances Prioritize tolerance, power per element, TCR (ppm/°C), max working voltage and noise figures on datasheets. These parameters indicate drift, thermal limits and suitability for analog vs. digital contexts. Datasheet Priorities Example BOM note phrasing: “Confirm 10 kΩ, 1/8W per element, 5% tolerance, 100 ppm/°C TCR, bussed configuration” — this focuses procurement and QA on the specs that matter for design risk. Test & Verification Verify arrays both in-circuit and out-of-circuit; confirm common-pin continuity on bussed parts, measure element resistance spread, and apply derating guidelines for elevated temperatures. Buying & sourcing playbook Sourcing Tactics Checklist: Match 10 kΩ, 8 elements, circuit type, power, and pinout. Do: Confirm pin mapping and TCR. Don’t: Swap bussed for isolated without layout change. Search phrase: “10k 8-element bussed SIP resistor network”. Ordering Strategy Buy samples for first-run builds, split production orders into immediate and scheduled replenishment batches. Negotiate packaging or MOQ where possible. Maintain a short approved-equivalents list. Sample inquiry: "Request current available qty, lead time, unit price and MOQ for part number; please confirm datasheet revision." Applications, design notes & replacement scenarios Use resistor arrays for pull-up banks, signal bussing and level-shift networks to save board space. Arrays reduce assembly steps and improve matching across channels. Common use cases Typical uses include pull-up grids on microcontroller ports, resistor ladders for level shifting and matched input terminations. Wiring example: each resistor connects from pin to common pull-up pin for open-drain inputs. How to choose an alternative (OOS Scenario) First match resistance and topology, then per-element power and package pinout. Verify mechanical fit and TCR; prototype-test any substitute. Search long-tail: “8BRN10K alternative resistor network” or “8-element 10k bussed SIP”. Summary ✔ Live-stock checks should capture timestamped qty, unit price, MOQ and lead time so buyers can compare channels and track price trends before committing to orders for the 8BRN10K Resistor Network. ✔ Prioritize tolerance, per-element power and TCR from datasheets; these specs govern drift, derating and suitability for analog vs. digital tasks. ✔ Procurement tactics: buy samples, split orders, set alerts and prefer distribution tier pricing for bulk buys while using marketplace listings for urgent small-quantity needs. Frequently Asked Questions How can I quickly verify 8BRN10K stock availability? ▼ Check distributor inventory feeds and marketplace listings with exact part numbers and alternate search phrases, capture timestamped screenshots or CSV exports and record available qty, unit price, MOQ and lead time. Automate alerts where possible and archive checks to observe short-term trends and spot markup patterns. What are the minimal datasheet specs to confirm before ordering? ▼ Confirm nominal resistance (10 kΩ), circuit type (bussed vs. isolated), per-element power rating, tolerance and temperature coefficient. These determine electrical fit, thermal limits and drift; noting them in BOM entries reduces risk of receiving mismatched parts for production runs. When is it acceptable to substitute a different resistor network? ▼ Substitution is acceptable only after verifying the substitute matches resistance, topology and pinout, then confirming equal or superior power rating and TCR. Prototype-test substitutes for electrical and mechanical fit before approving them for full production to avoid rework or failures.

23 January 2026

0

4310R-101-222: Complete Spec Breakdown & Performance Data